Technology Platform

Related Services and Solutions

We look forward to working with you and providing you with excellent service.

Solubility Enhancement

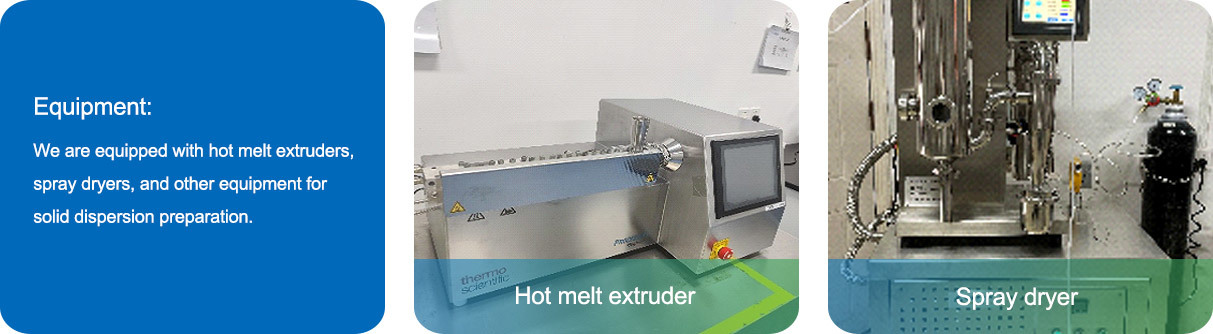

Current methods for enhancing the solubility of poorly soluble drugs include cyclodextrin inclusion complexation, solid dispersion, solubilizers or co-solvents, synthesis of water-soluble prodrugs, nanosuspension, liposomes, and hot melt extrusion. We have developed sophisticated hot melt extrusion and spray drying techniques for drug solubilization, and successfully delivered related projects.

Applications

● Hot melt extrusion: Hot melt extrusion (HME) is suitable for thermally stable drugs, and is commonly used to prepare amorphous solid dispersions to improve the bioavailability of poorly soluble drugs. Compared with spray-dried dispersions, hot melt extrusion is lower-cost and compatible with drugs that exhibit poor solvent solubility and stability. HME can also be used to prepare sustained- and controlled-release drugs, providing flexible formulation solutions to achieve desired drug delivery systems. Representative products: Posaconazole enteric-coated tablets.

● Spray drying: Spray drying involves atomizing the raw material and carrier solutions into fine droplets that are sprayed into a chamber with controlled temperature, humidity and airflow, to form solid dispersions upon evaporation and drying. Spray drying significantly increases the dissolution rate of poorly soluble drugs, which improves in vivo bioavailability. Representative products: Apalutamide tablets, telmisartan tablets.